Unser Leistungsangebot

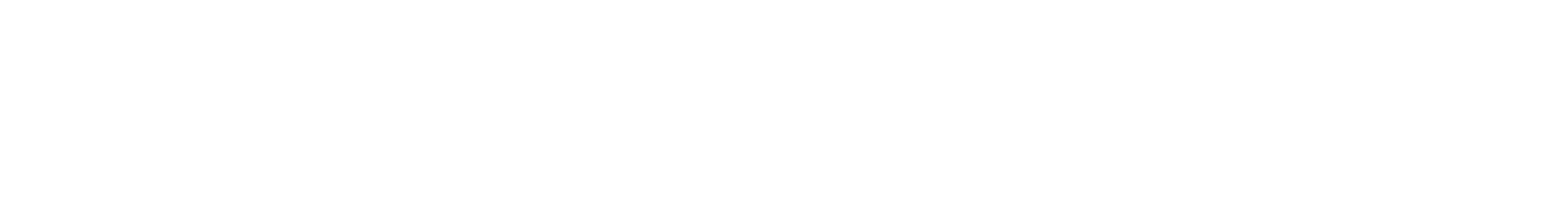

Hochvakuumlöten

In unserem Haus werden ausschließlich alle CBN Werkzeuge hochvakuum gelötet, was folgende Vorteile mit sich bringt:

-gleichmäßige Wärmeeinbringung

-geringe Spannungen im Bauteil

-Verbindungsfestigkeit die den Grundwerkstoffen nahe kommen

-dünnwandige und formkomplexe Bauteile können besonders verzugsarm gefügt werden

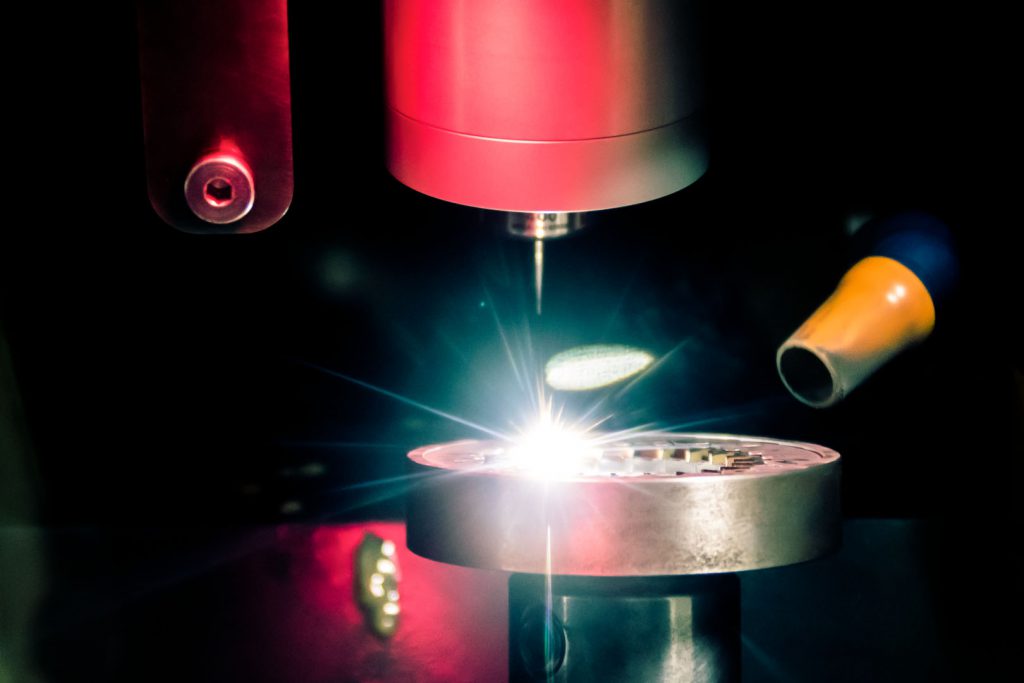

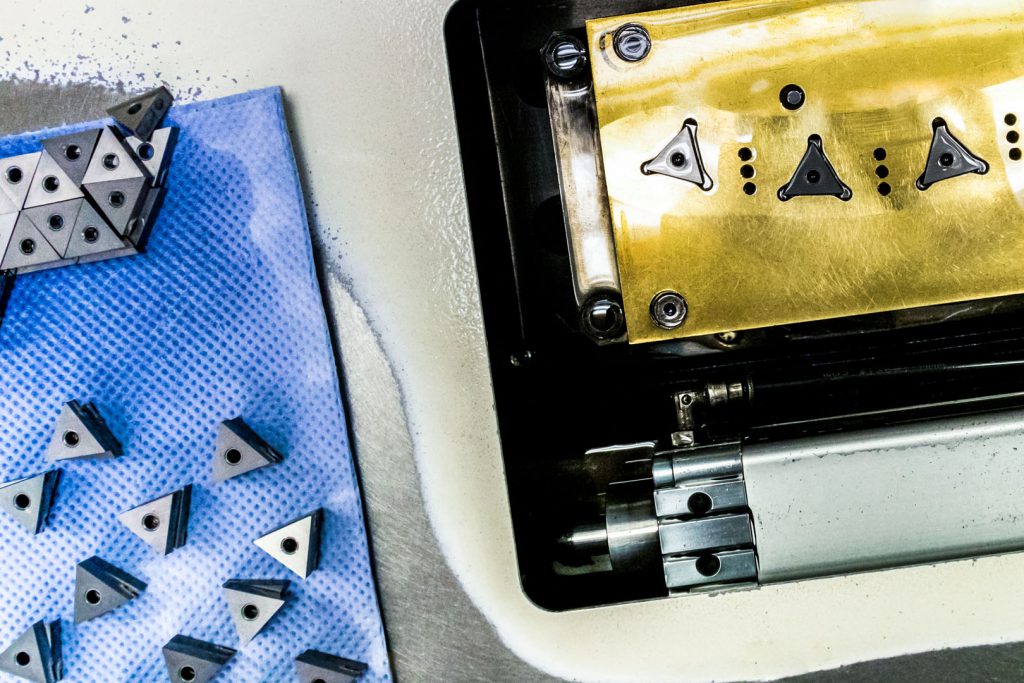

Schleifautomation

Unsere CBN-Standart Wendeschneidplatten werden alle auf mittlerweile zwei vollautomatisierten Schleifautomaten hergestellt, dies garantiert höchste Wiederholgenauigkeit in engsten Toleranzen.

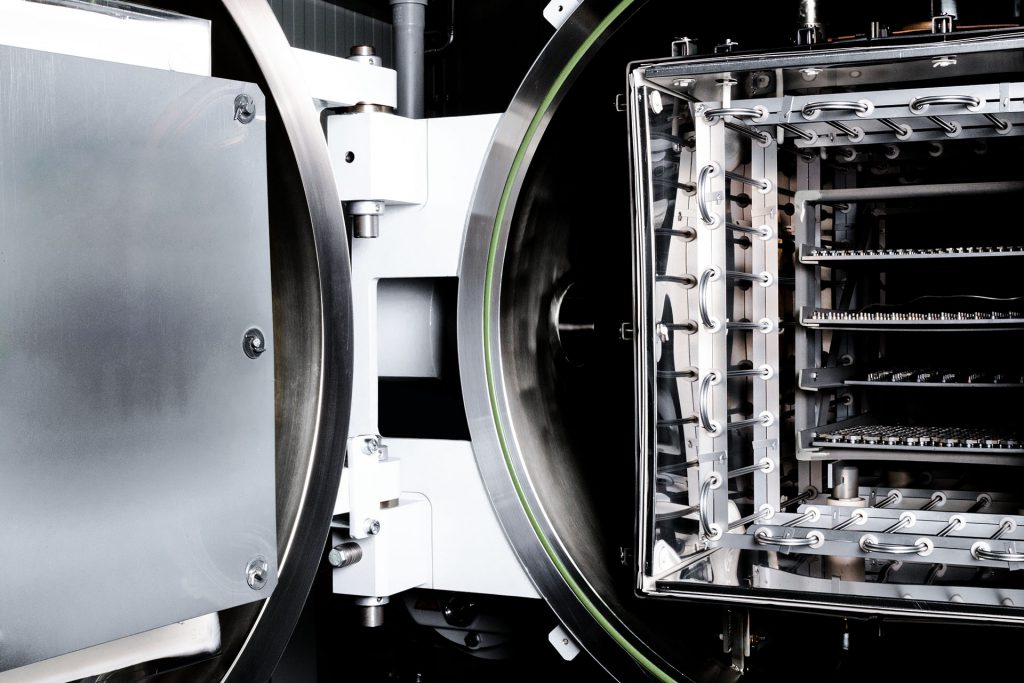

Lasertechnik

Die Lasertechnik ist die neuest Generation der PKD bearbeitung. Der wesentliche Vorteil ist, das der Laser das Korn schneidet, was bei der Drahterosion und beim schleifen nicht möglich ist. Es ist möglich kleinste Profile auch ohne Innenradien (Drahterosion) herzustellen.

Erodierservice

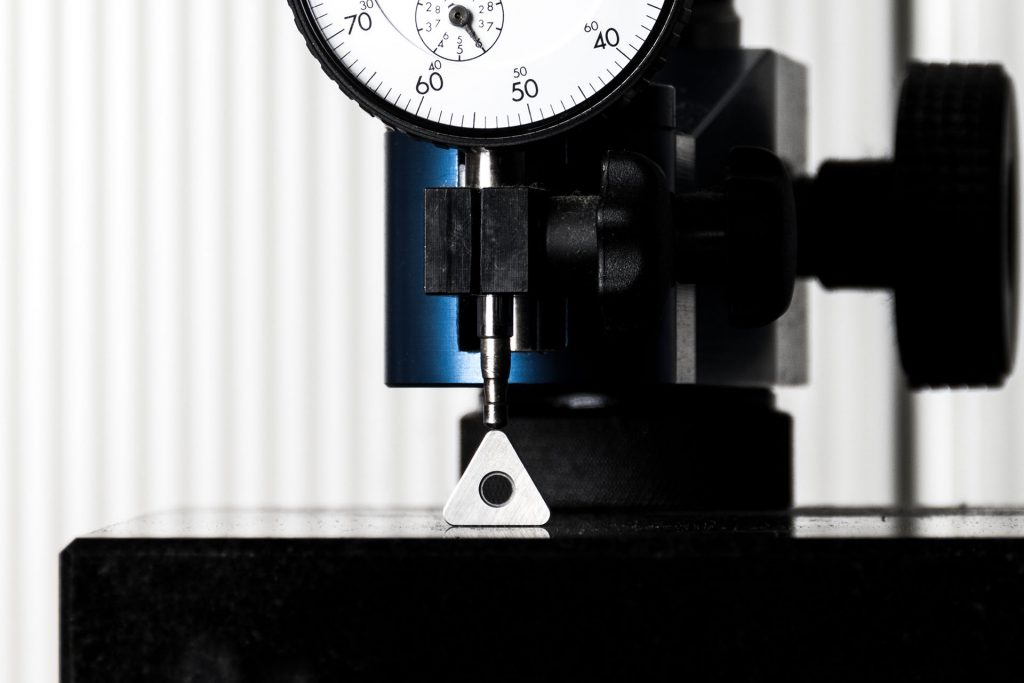

Messtechnik

Automation